thin film hardness testing|Mechanical Behavior of Thin Films : bulk According to presented results, several key-points can be extracted and formulated into a set of recommendations to measure the mechanical behavior of thin films . See more Resultado da 21 de jan. de 2020 · Banca de Concursos Públicos: CONPASS. Questões, Provas e Últimos Concursos realizados em todo Brasil. Veja como ser .

{plog:ftitle_list}

1 de mar. de 2004 · Counter-Strike: Condition Zero. With its extensive Tour of Duty campaign, a near-limitless number of skirmish modes, updates and new content for Counter-Strike's award-winning multiplayer game play, plus over 12 bonus single player missions, Counter-Strike: Condition Zero is a tremendous offering of single and multiplayer .

Toughness measurement of thin films: a critical review

As a direct result from nanoindentation the load–displacement (P–δ) curves were extracted. P–δcurves exhibit expected behavior for all examined cases. The indentation with the lowest load shows linear, elastic material behavior, but with increasing load plastic deformation starts to play a significant . See moreTo explain such a large dependence of the E and small dependence of the H on the hc/tfor surface indentation and to visualize the resin deformation during the . See moreAccording to presented results, several key-points can be extracted and formulated into a set of recommendations to measure the mechanical behavior of thin films . See moreThis article gives an overview of current techniques to determine hardness, Young's modulus and stress state of a thin solid fIlm on a substrate. The former two are measured with an .

Researchers are currently working on the measurement of the hardness of the thin films. All of them apply 10% rule in their studies. Accordingly, when a hollow‐shaped hole is made on the . In this chapter, we tried to formulize and explain the methods that can be used to measure the hardness of a thin film, the parameters affecting the hardness of a thin film, .During this webinar, Dr. Pal-Jen Wei discusses challenges and strategies for successful thin film hardness and modulus measurements. Dr. Wei reviews: Nanoindentation for mechanical property metrology. Substrate effects when .

As thin films are increasingly finding their way in engineering applications, thin film toughness assessment becomes imperative. Unlike the bulk materials, however, until now, . A quite different approach to measuring the hardness of thin surface films would be to quantify how the film and the substrate interact and give the measured composite .Specialized experimental techniques have been developed to determine mechanical properties and the strain and stress states of both free-standing films and films bonded to sub- strates. .Common methods of testing freestanding films, including uniaxial tensile testing, uniaxial creep testing, biaxial testing, and beam-bending methods, are discussed. For films which are .

Enormous progress has been achieved over the past decade in evaluating the toughness of hard coatings and thin films. This paper reviews methodologies developed .ASTM D3364 and ISO 15184 — These are the internationally accepted test methods for film hardness. These are convenient, inexpensive, and quite accurate test methods. Here many grades of pencils from soft to hard, are used to evaluate the film hardness. . — This instrument is used to test advanced thin film coating. AFM enables the imaging . This is mainly caused by the mismatch in mechanical properties between thin film/ thin film or substrate/ thin film interfaces, such as differences in coefficients of thermal expansion (CTE), Young’s modulus, or Poisson’s .

Hardness testing can be applied to various types of materials, some of which are listed below: Metals and alloys. Ceramics. Elastomers. Polymers and plastics. Films. Rocks and minerals. Importance of Hardness . Recent developments in microtensile testing of thin films will be emphasized, especially the application of macrotension to a substrate in order to induce microtension in a patterned thin film. Commonly used qualitative methods will be described first. . hardness, Poisson's ratio, and the hardening exponent of a coating or a film; .

Due to the deformation of thin films, Ferro et al. could only show that there is a negative relation 22 between thickness and hardness of the film: (i) the boundary between the film surface and .

Microhardness, thin films, small parts: 1-100 kgf: Diamond Pyramid: ASTM E92, ISO 6507: Knoop: Brittle materials, ceramics, thin coatings: . Hardness Testing Results for Reliable Material Performance. Hardness testing is a fundamental practice in materials science and engineering, providing crucial insights into a material’s resistance to .

Learn how to collect high-accuracy, high-confidence thin film hardness, adhesion, and cohesion measurements under controlled environmental conditions. . Ph.D., provides a detailed exploration of the principles and practical applications of nanoindentation and nanoscratch testing of thin films for industrial applications. This includes showing .

(a) Hardness H and (b) reduced elastic modulus E r results for the nanoindentation with Blunt, Standard and Sharp tip as a function of the contact depth h c (with reference values of E r, Si, H Si . Mechanical properties form the last major group of properties which have important applications in thin films. The hardness of a material can be modified by the deposition of a thin film having a different surface hardness (i.e., harder or softer) than the material on which it is deposited. . Hsu FC, Sun PK, Lin MT (2013) Cyclic creep and . The adhesion strength of thin films is critical to the durability of micro and nanofabricated devices. However, current testing methods are imprecise and do not produce quantitative results .The DuraVision universal hardness testers for standard load ranges of 0.3-250 kgf or 3-3,000 kgf can be used for Vickers, Knoop, Brinell, and Rockwell tests, as well as for carbon and plastics testing.All methods are covered by the ISO 6506, ISO 6507, ISO 45452, ASTM E384, ASTM E92, ASTM E10, ISO 6508, ASTM E18, DIN 51917 and ISO 2039 standards. The DuraVision .

Thin Film Characterisation Methods – Hardness/Adhesion – Nanoindentation – Plasma Diagnostics and Particle Flux Analysis – Raman Spectroscopy – Film Thickness – Magnetometer (VSM) and High Frequency Permeameter – X-ray Diffraction XRD/XRR Characterisation Technologies Hardness /Adhesion Nanoindentation

Toughness evaluation of hard coatings and thin films

Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find qualitative relations to other material properties (e.g., strength, stiffness, density) or to the material behavior under certain stresses (e.g., abrasion . ISO/TS 19278 standard enables precise hardness testing of plastics, even for thin or small specimens, using the DUH-210 tester. . On the other hand, the issues below arise in Rockwell hardness tests of plastics. With thin-film specimens and small specimens the correct measurements are not possible due to the large force. In addition, when the .

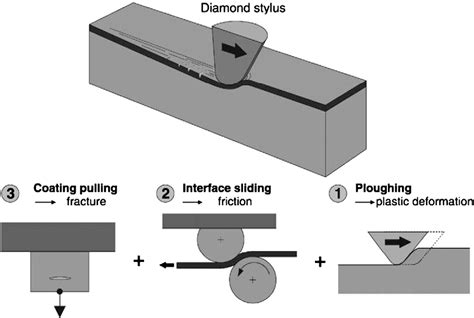

We have measured hardness i.e. scratch hardness from the scratch tester usually used for investigating adhesion in thin films and compare this with hardness measured by the nanoindentation technique on copper thin films. We defined scratch hardness as the load per unit load-bearing area during scratching, calculated from applied load and the .The Micro Hardness Tester takes center stage when it comes to examining the hardness of materials at a smaller sample, thin specimens, plated surfaces or coatings. . polymers, and thin films. The ability to characterize the .Hardness test methods use an indenter probe that is displaced into a surface under a specific load. In traditional testing, the size or depth of indentation is measured to determine hardness leading to user bias in the data. . Thin .We have measured hardness i.e. scratch hardness from the scratch tester usually used for investigating adhesion in thin films and compare this with hardness measured by the nanoindentation technique on copper thin films. We defined scratch hardness as the load per unit load-bearing area during scratching, calculated from applied load and the .

Versatile Leeb hardness tester for on-site testing of large rolls, thin foils, and films. Top. Workspace EN English; Deutsch . Large crown for a safe and stable impact for fast and reliable hardness testing of paper, film, foil, textile, cardboard, and leather rolls. Versatility This hardness test type is used for thin sheet materials or components prone to bend or wrap due to normal hardness testing conditions. Rockwell Superficial Hardness Tester uses a regular Rockwell indentor but under reduced test load. . Both Vickers and Knopp Microhardness tests are used for hardness testing of thin materials, thin-film .We offer a suite of physical and mechanical testing, including bespoke or standard test methods (ASTM, ISO) to help understand the coating’s durability and performance including coating thickness, density, hardness and scratch resistance. We can also perform adhesion property testing and opacity /optical, thermal and rheological properties.

a low force, hardness testing of even small specimens and thin-film specimens is possible, and hardness is evaluated by the same scale irrespective of the type of material. This article introduces hardness testing conforming to the above-mentioned standard (ISO/TS 19278:2019) by the Shimadzu DUH™-210 Dynamic Ultra Micro Hardness Tester for .The iNano ® nanoindenter makes measuring thin films, coatings and small volumes of material easy. The accurate, flexible, user-friendly nanoindentation testing instrument can perform a wide range of nanoscale mechanical tests including indentation, hardness, scratch and universal nanoscale testing.Vickers hardness testing can be used for microhardness testing, allowing for the measurement of hardness in small or thin samples. This capability is essential for materials with limited sample sizes or complex geometries, such as thin films, coatings, or small components. 7. Non-Destructive Testing

Unlocking the Mysteries of Hardness Testing. At the heart of hardness testing lies the quest to gauge a material’s resilience against localized plastic deformation, primarily through penetration. These measurements craft a roadmap, guiding predictions about wear resistance, tensile strength, and a plethora of other pivotal properties. Vickers .

When testing coatings, scratch hardness refers to the force necessary to cut through the film to the substrate. The most common test is Mohs scale, which is used in mineralogy. One tool to make this measurement is the sclerometer. Another tool used to make these tests is the pocket hardness tester. This tool consists of a scale arm with . Simple equations are proposed for determining elastic modulus and hardness properties of thin films on substrates from nanoindentation experiments. An empirical formulation relates the modulus E and hardness H of the film/substrate bilayer to corresponding material properties of the constituent materials via a power-lawrelation. Geometrical dependence of E .

Rubber Abrasion Tester services

Fatos [Tombense] 8 Jogos. 2 Vitórias. 25% 4 Empates. 50% 2 Derrotas. 25% 5 Gols. 0,63 G/J. Q. 4 Gols sofridos. 0,5 G/J. Q. Totais. 50 % Empates. Totais. 25 % Jogos. Em que marcou. + Info. Totais. 50 % Jogos.

thin film hardness testing|Mechanical Behavior of Thin Films